The photopolymer is designed to produce high-quality castings. It is used for casting dental implants and jewelry. Resin provides high detail and print...

Подробнее-

Тип:

Промышленные -

Производитель:

Additive Plus -

Вес/объём:

1 л

-

Доставка

по России и СНГ -

Установка

и пусконаладка -

Расходные запчасти

и материалы -

Обучение персонала на месте

-

Гарантия и сервисное обслуживаниеx

Описание

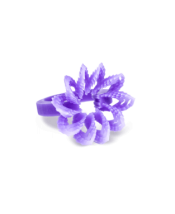

The photopolymer is designed to produce high-quality castings. It is used for casting dental implants and jewelry. Resin provides high detail and print accuracy.

Peculiarities:

- High strength, resilience and elasticity;

- Wide application in the manufacture of fittings;

- High indicators of density and viscosity;

- Liquid without impurities and sediment;

- The polymer is stable when stored properly;

- Expiration date for printing - 12 months.

Burn mode:

- Stage 1 - into a cold oven, heating to 150 ° C at a maximum speed, hold for 180 minutes

- Stage 2 - raising to 260 ° C in 4 ° C steps, hold for 180 min

- Stage 3 - rise to 950 ° C in 2 hours 20 minutes, hold for 300 minutes

- Stage 4 - cooling to the casting temperature

On exposure, the question may arise: “As such, exposure of the burned-out polymer is obligatory or not? If so, how much does it cost to keep in a UV camera? "

And we answer: it all depends on the model: if it is small, graceful - washed and dried, and if it is large, then it takes a minute to light up. But here is a universal recommendation so as not to rack your brains: determine by yourself by the surface - if after rinsing it is not sticky, then you can not light up, it is not necessary.

| Smell | weak |

| Density at 20 ° С | 1155-1175 kg / m3 |

| Dynamic viscosity 23 ° С | 90-110 mPa * s |

| Kinematic viscosity | 90-100 sSt |

| UV curing wavelength | up to 410 nm |

| Shore hardness | 72 steps D |

| Breaking strength | up to 12 MPa |

| Elongation at break | up to 34% |

| Shrinkage | 0.9% |

Color: translucent yellow

Характеристики

-

Страна

Россия -

Тип

Промышленные -

Производитель

Additive Plus -

Вес/объём

1 л

Запросите КП и вы получите:

- Стоимость в рублях или валюте

- Комплектацию поставки

- Стоимость расходных материалов

- Технико-экономическое обоснование

- Сроки и условия доставки

- Перечень дополнительного оборудования